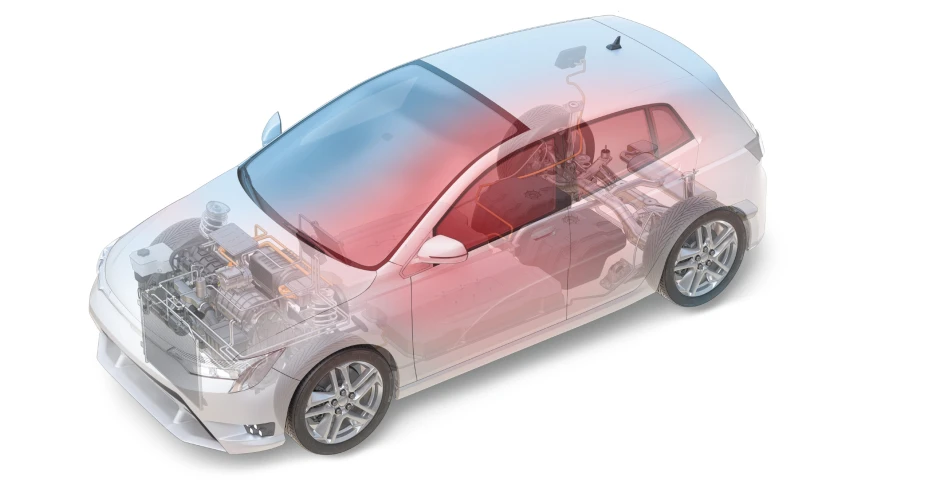

Unlike a conventional vehicle’s Aircon system, a heat pump based system is capable of both heating and cooling. Nissens explains how it also manages the vehicle’s component and battery pack temperature, helping the car conserve battery life and extend its driving range.

The heat pump solution is one of the most efficient ways of producing heat. Depending on the system type, the heat pump can reach above 300% efficiency, compared to an electrical heater.

Characteristics of the heat pump solution offer a number of advantages for vehicles driven by electricity.

H/E Vehicles heating issue - H/E Vehicles do not produce enough thermal energy to efficiently warm up the vehicle cabin.

Waste-heat employment - The heat pump utilizes the heat produced by E/H vehicle electrical components.

Extended drive range - There is no longer need for employment of electrical high-voltage heating that drains the vehicle battery.

Tools Required High voltage tools Use only approved equipment and insulated tools and protective gear certified for minimum of 1000 volts.

High-pressure tools If the system is charged with R744 (CO2), use only approved tools for the refrigerant. The recovery and filling station, connector, hoses, and pressure gauges must be R744 (CO2)-dedicated.

Wireless tools A precise digital thermometer, wireless clamps, or gauges will ease properly determining the system parameters.

Compatible OBD An OBD solution that is compatible with the serviced vehicle and capable of detecting the heat pump system is required for the service.

Safety Many parts in the NEV A/C system are high-voltage and require special safety procedures. Follow dedicated procedures and use protective equipment and tools.

Only certified technicians can carry out service work. Consult the manufacturer’s safety guidelines and learn more about safe handling in Nissens’ separate guidance.

Vehicle data The vehicle’s OE documentation is the key for a regular workshop in the aftermarket to service these cars. Learn the specific system you’re about to work on.

System layout info, technical notes, bulletins, and service procedure information will ease the process and enable you to perform any diagnostic work correctly.

Standard Procedures Initial Inspection In the initial inspection, include the service steps you know as standard for the conventional A/C system.

- System performance check in all heating/cooling modes

- Loop visual control

- Control of loop components temperature

- System static and working pressures

- Loop tightness/integrity

- OBD and electrical system test

To read more of this technical article or download the entire article click

here. There are lots more Tech Tips to view, and they are all searchable, on

TechTips.ie.

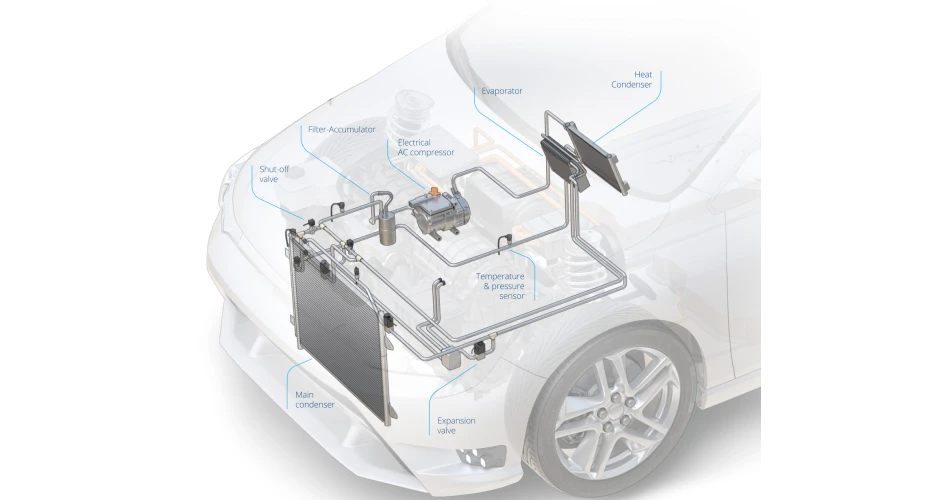

Heat pump system layout

Heat pump system layout