One of the leading trends affecting the automotive industry, is the shift towards environmental sustainability. One solution for sustainability is the two-piece brake disc range containing floating, riveted and co-cast options, which has real benefits compared to an integral (one piece) brake disc. Here Brembo explains the advantages and changes to fitting for these discs.

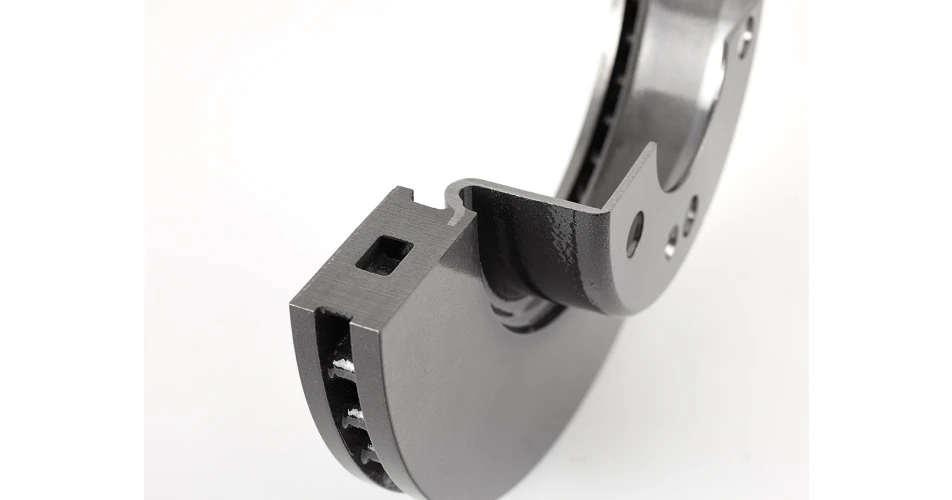

The standard integral brake disc has traditionally been manufactured out of cast iron, due to its durability and heat dissipating qualities. The two-piece solutions, such as the floating brake discs, are manufactured with an aluminium hub and a cast iron braking surface. The disc hub and the braking surface are two separate components that utilise fastening bushings to connect the two parts. The use of these lightweight materials provides a weight reduction of up to 30%, with a subsequent reduction in engine emissions. This change in design, which sees the connection of the disc hub to the braking surface, also allows for the braking surface to expand without distorting the hub.

Introduced in the early 2000s, floating discs were initially a feature exclusive to sports cars and supercars. However, in recent years many other vehicles, even in the mid-range, have benefited from the advantages of bi-material braking systems; specifically compound discs and co-cast discs.

In comparison to the floating solutions, riveted brake discs feature a steel hub and a cast iron braking surface, which are connected together by means of a special rivet steel.

Later, Brembo developed the co-cast brake disc, which also features a steel hub and a cast iron braking surface. The hat, however, is connected to the braking surface by being casted in the braking surface.

The steel hat guarantees a reduction of about 15% in the weight of the disc, compared to an integrated disc of the same size. The disc surface is coated with UV technology that guarantees higher resistance to humidity and elevated temperatures. Additionally, the UV coating is water-based and does not require solvents, which generates a 98% savings in energy and emissions compared to conventional coatings. To provide further weight savings, the steel hat of both riveted and co-cast brake discs, is manufactured to a thickness of 2.5 mm, instead of the 7.5-9 mm of a conventional cast iron housing, with the same level of performance.

By reducing the weight of a disc, all composite solutions ensure an increase in available engine power and, thus, a reduction in the fuel consumption and emissions of the car. This also improves the handling of the car, which results in more precise and stable vehicle dynamics.

Replacement guidelines for two-piece discs Bearing in mind the difference in design and materials that are used on two-piece brake discs, there are some crucial points to take note when handling and fitting these discs.

• Due to the decreased thickness of the disc hat, DO NOT pick up or handle these brake discs by the steel hat, as this might cause minute distortions and lead to excessive lateral runout and the onset of brake judder.

• Thoroughly clean the surface of the wheel hub and the disc before installation.

• DO NOT turn the steering wheel by holding the disc/caliper. This will lead to distortion to the reduced thickness, lightweight steel hat.

• When refitting the wheel, follow the correct torque sequence as well as the manufacturer’s recommended tightening torque.

• Tighten the wheel screws in three steps.

1. Position by hand

2. Initial torque 75 Nm

3. Final torque (refer to the car manufacturer’s instructions)

• Only original OE quality rims should be used to prevent disc deformation.

Please take note: an increase in noise, vibrations or harshness could be the outcome of not following the above fitting guidelines, or replacing these discs with integral discs.

To read more of this technical article or download the entire article click

here. There are lots more Tech Tips to view, and they are all searchable, on

TechTips.ie.

The hub and braking surfaces are two separate pieces

The hub and braking surfaces are two separate pieces