Hamburg-based spare parts manufacturer MEYLE has made further additions to its range of technically refined MEYLE‑HD axial joints to fit passenger car and van models. The full range of MEYLE‑HD axial joints now provides for 74 million vehicles registered in markets across Europe.

High tensile and compression forces acting on the steering system, experienced for example when hitting a pothole, crossing kerb stones or steering while car is stationary, are a frequent cause of early joint wear and excessive axial joint play. While conducting on-going evaluations of vehicle inspection reports, the German Technical Inspection Agency (TÜV) has revealed that the defect rate is particularly alarming with vehicles that are between three to five years old. The Sprinter and Transporter models stand out as a high-risk group because of the extraordinary strain levels the joints have to put up with, which result from heavy payloads.

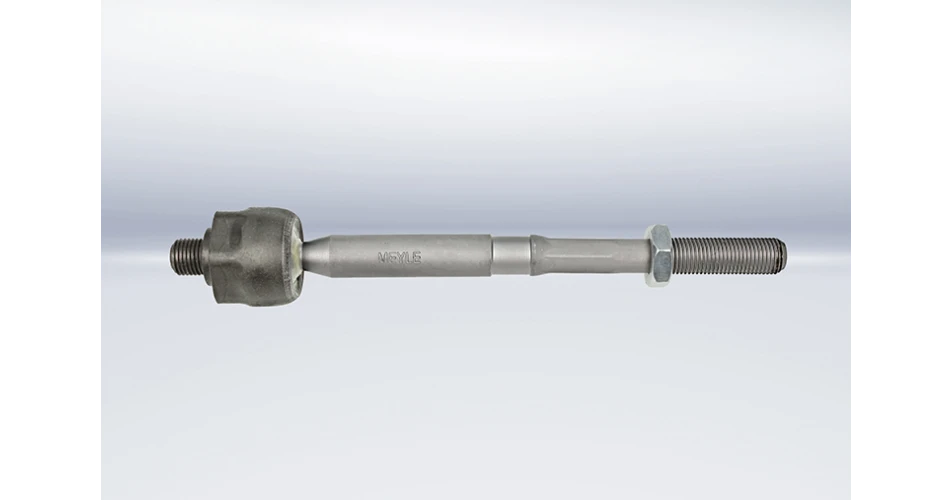

Axial joints ensure that steering motion is precisely transferred to the wheels. If the axial joint is worn, the impact on the vehicle systems can be dramatic, with the consequences ranging from perceptible steering play, uneven tyre wear and difficulties passing routine vehicle inspections, to an increased risk of being involved in a road accident.

Sven Nielsen, Head of Strategic Product Development at MEYLE says, “When developing MEYLE‑HD axial joints, we scrutinised OE joint designs to pinpoint the root causes for early product failure and then we set about engineering a solution targeted at remedying these weak points.” He adds, “Take for example the ball head: MEYLE‑HD joints feature a significantly larger ball head than their OE equivalents. This allows for the forces acting on the joint to be distributed across a much larger surface area, which in turn, reduces surface pressure while increasing part life. Depending on the application, the ball head diameter of the MEYLE‑HD axial joint can be up to 5mm larger than its OE counterpart.”

A further benefit is the MEYLE part's special zinc-nickel coating which is was proven to offer excellent corrosion resistance, while a further feature adding workshop value is the wrench attachment, which allows for simple and quick assembly of the MEYLE‑HD axial joint without requiring any costly special tools.

MEYLE uses computational models for in-process simulation and monitoring of the power flow dynamics during the product development. Targeted technical refinements eliminate any weak points, component design is reinforced and higher-grade materials are chosen. All MEYLE‑HD products come with a four-year unlimited-mileage guarantee. Since it was launched, the MEYLE‑HD product range has grown to feature some 1,000 products catering for passenger car, van and truck models.

MEYLE and MEYLE HD parts are available from stockist nationwide and are distributed in Ireland by Strongline Autoparts. For more information call 01-462-4631.