A recent helpline call was an issue with a poor performing air conditioning system on a Nissan Note. The technician had performed a basic refrigerant service, but the system was still not cooling efficiently.

We asked for the pressure readings from the AC service gauges with the system switched on and in maximum cooling and the fan at speed 3. It was immediately obvious that the pressures were not correct. The High side pressure had not risen to the expected level and the low side pressure had dropped slightly from the static pressure.

We asked for the thermal expansion valve to be removed and inspected, and instructed the technician how to test for the correct operation of the valve. The technician had no knowledge of this component. It was proven to be stuck in the fully open state, so a new valve was fitted. And the system was vacuumed out and refrigerant added.

On starting the system, the pressure now was at a much better level, but the compressor was very noisy. A new compressor was fitted, but failed in a very short time after starting up.

The technician did not understand that the compressor did not actually come prefilled with refrigerant oil, and only added 10 ml of oil via the refrigerant machine, as he usually did during a service.

The first mistake he made was not cleaning the system out after the first compressor was found to be faulty. The contamination from the first compressor, plus lack of lubrication in the second compressor, spelled disaster. A simple lack of training in the processes involved in AC diagnostics ended in a costly repair.

We advised the system would require a complete flush before a new compressor fitting, and the oil should be added direct to the unit before fitting.

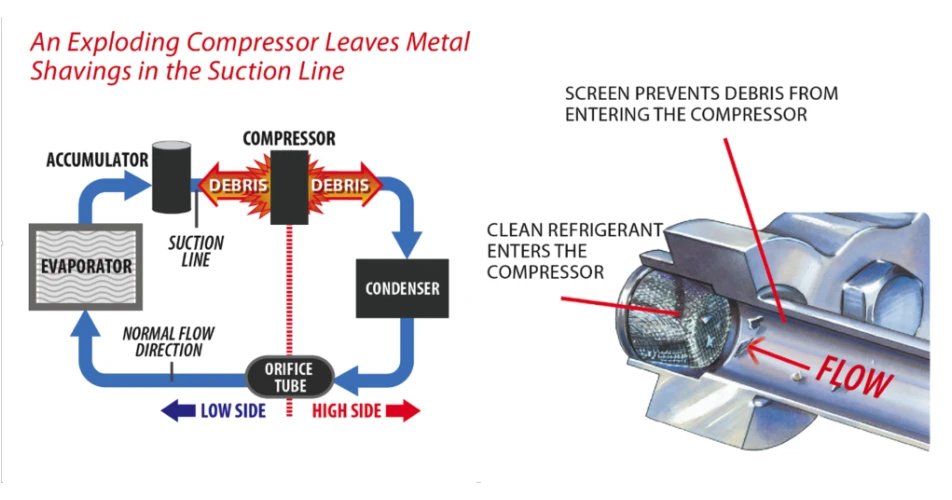

As a secondary precaution, we suggested fitting of a compressor guard system, in the event of any unseen debris was still in the system.

A simple stainless-steel screen was inserted into the inlet port of the compressor that catches any stray debris inside the refrigerant circuit. This can be removed and cleaned during subsequent AC service intervals.

This may seem like basic testing processes, but to gain your Fluorinated gas certification, before you can work on Vehicle AC systems, does not always involve any system training on the repair processes.

The safe handling of Fluorinated gases is the main focus of the available courses, and they expect you to continue your training on up to a system repair level of knowledge. Unfortunately, this rarely happens and just holding the F-gas certification seems to be enough for most employers.

A costly mistake that could have been avoided with continued technical training.

To see or download this article click

here. There are lots more Tech Tips to view, and they are all searchable, on TechTips.ie.

To join the Autobiz Helpline, call 01-905-9500, and then press 2, for further information.

Protecting a new compressor from the debris of the failed one

Protecting a new compressor from the debris of the failed one