In a recent edition of Autobiz, we explored the common issues faced by workshops diagnosing modern air conditioning systems, and the issue with compressors that had failed to operate, for many reasons. Most workshops are now equipped with various air-conditioning recharge stations, as nearly all vehicles sold have some form of climate control. The revenue AC servicing provides makes good business sense.

The problem the Tech. Helpline encounters on a regular basis, is when the system does not operate as expected. Most technicians have the basic knowledge of how the refrigerant systems works, but little understanding of the working principles behind the system they are trying to diagnose. This is where the understanding of refrigerant pressure and temperature play a major role in diagnosing such systems. And to understand what is taking place at various points in the system, can improve their chances of a fix.

First, we can see that R134a, a common refrigerant used in vehicles, has a certain temperature pressure range. To see what these are, we would refer a readily available refrigerant pressure chart for the refrigerant under test.

Secondly, to understand that it is heat energy that we are dealing with, not cooling. The system is designed to remove heat from the cabin and transfer this heat to the surrounding air outside the vehicle. This is something that is not readily understood when working on these issues.

As you can see in this chart the temperature of R134A @1.92 Bar is 0 deg. C

With a low side pressure reading of 1.92 Bar, the evaporator saturated temperature would be around 0°C. As heat energy will travel from high to low, the warm air inside the cabin would be absorbed into the cold refrigerant, but it would not raise the temperature of the refrigerant until it reaches its boiling point. Then the refrigerant would change state into a gas, just as it leaves the evaporator. Measuring the temperature at this point we should see a rise in temperature, this is referred to as superheat. This rise in temperature would indicate the refrigerant has absorbed the maximum heat energy possible inside the evaporator.

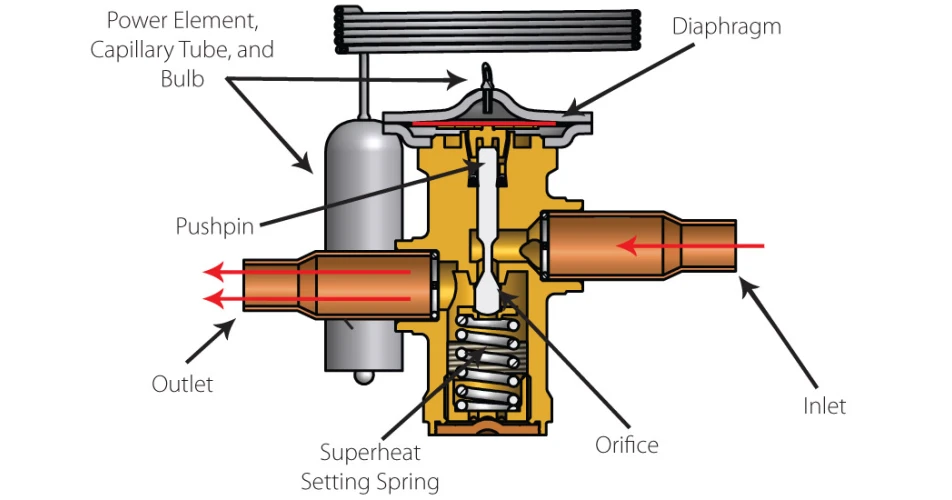

The flow of refrigerant is controlled by either a fixed orifice jet or a thermal expansion valve (TXV). Both are designed to control the flow into the evaporator, and this is where the pressure in the system takes place. The TXV has more control over the flow, by varying the size of the orifice while monitoring the temperature at the evaporator outlet. A typical superheat temperature would be around 5 to 8°C above the saturated evaporator temperature. Too high a super heat indicates a low state of charge in the system.

It is important that the refrigerant leaving the evaporator is in a gaseous state, as the compressor is not designed for liquid.

Once the refrigerant gas is compressed and enters the condenser at a high temperature, the same principle comes into play. Heat energy will travel from high to low. Heat will be released into the surrounding air, and the pressure of refrigerant in the high side circuit will indicate the saturated core temperature. Typically, a 10-bar high side pressure of R134a will have a condenser temp of 44°C.

You can find a pressure temperature chart at

www.igasusa.com/pt-charts/R134A-PT-Chart.pdf The temperature will not change during the release of heat energy inside the condenser until the refrigerant reaches its condensing temperature, where it will change state from a hot saturated gas into a liquid.

At this point, the refrigerant temperature will begin to drop, indicating it has condensed and released its heat energy. The drop at the condenser outlet is called subcooled refrigerant, typically a drop of 5 -10°C. Any higher and it indicates condensing occurred early and backing up in the condenser, a sign of too high a refrigerant charge.

Monitoring the superheat at the evaporator outlet and the subcooled refrigerant at the condenser outlet, can aid with the overall system performance. Understanding the function of the TXV or fixed orifice where the pressure change takes place, and the temperature drop that occurs with this temperature change, is vital. A blocked Orifice or TXV can be diagnosed by monitoring the pressures on both sides of the system. Monitoring the temperature inside the evaporator via the low side pressure, an ideal temp would be just above 0°C. Any lower and it would freeze.

The importance of removing all moisture from the system is vital, making sure the vacuum phase of servicing the AC system is sufficiently long enough to boil off the moisture to extract it. Water boils into a vapor at just over 29 in Hg at around 15°C, so the longer you leave a vacuum on the system, the more moisture will be removed.

So AC servicing does not end when you have re-gassed the system. The service is not complete until you have monitored the pressures and temperatures in the system you are working on, and they are all at the proper levels.

You can

download this story as a PDF, as well as other technical tips at TechTips.ie.

There are lots more Tech Tips to view, and they are all searchable, on

TechTips.ie.