As technicians become increasingly familiar with the job of timing belt replacement, they are regularly reminded of the importance of ensuring that the new belt is fitted correctly, as the repercussions of a poor quality job can be expensive. Unfortunately, the same thought is rarely given to the auxiliary belt, even though the failure of which can sometimes be equally catastrophic.

The auxiliary belt is often overlooked with regard to technical direction or training. This attitude can be a false economy, especially as the demands on the auxiliary belt are increasing with air conditioning compressors and start-stop alternators becoming more common.

Dayco is promoting best practice, even for the humble auxiliary belt. Although 'elastic' belts such as the Dayco Poly-V Elastic range need no tension adjustment, it is essential that the technician install the belt using the correct tools.

Historically, many technicians have simply 'hooked' these belts onto the pulleys with the use of a screwdriver or a wrench, but these tools are totally inappropriate and can cause direct damage to the belt, which could result in the pre-mature failure of the belt. Although on first thought, an auxiliary belt failure might be considered an inconvenience rather than a disaster, it is worth taking a moment to consider that in many cases timing belt failures are caused by a foreign body, such as the auxiliary belt, entering the timing belt drive.

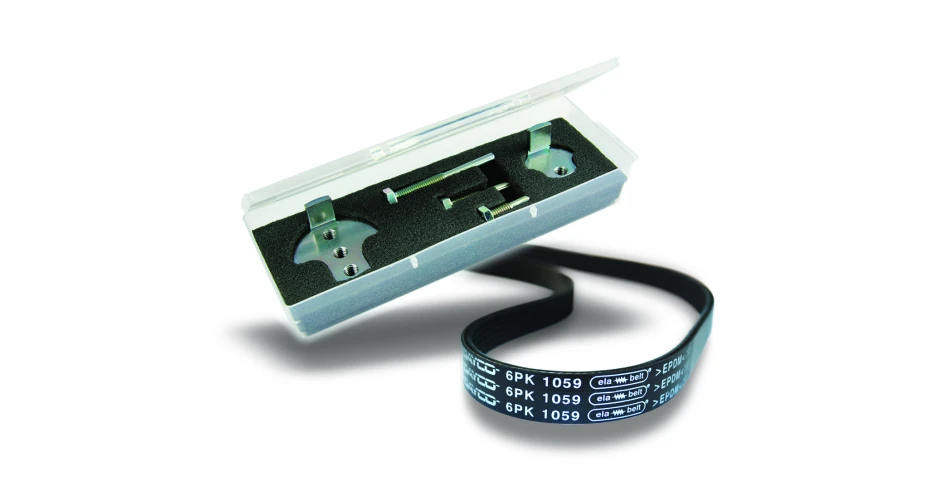

Dayco have an elastic belt fitting tool, the Dayco universal fitment Tool6, which covers the range of elastic belts offered by Dayco. The tool is specifically designed to install these belts quickly and correctly, avoiding any crimping, nicking or any other sort of damage to the belt if this tool is used, and without harming the running surface of the pulleys.

According to Dayco, the use of this tool will also ensure that the replacement is completed in the most time-efficient manner, which saves the workshop money in two ways; the job is completed correctly without a subsequent claim and it is quicker, and therefore a more profitable job to undertake.

Dayco is including the specific fitting tool for the Ford 1.4, 1.6 petrol Focus/C-Max applications with their Poly-V PVE001 and PVE002 belt kits, as these applications are not suitable for its Tool6 universal fitting tool.

For more information contact PR Reilly on 01-832-0006, email info.uk@daycoeurope.com or logon to www.dayco.com.