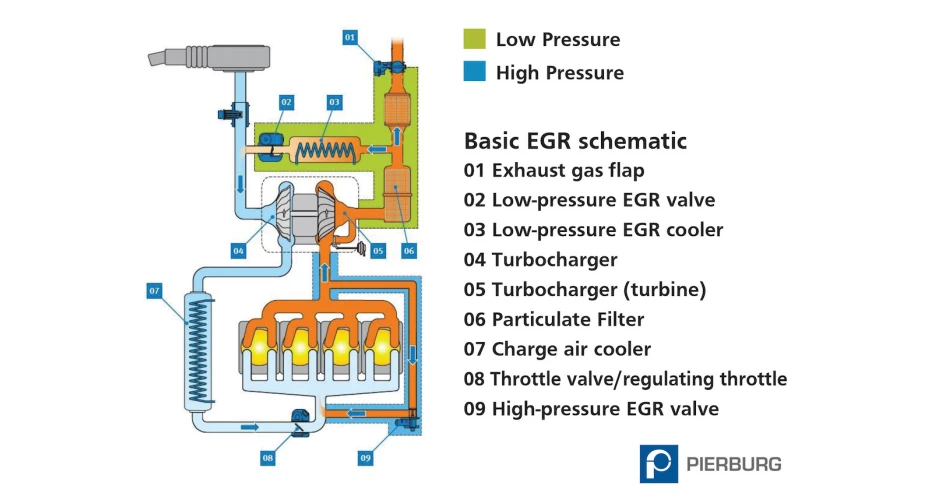

Exhaust Gas Recirculation (EGR) is an effective emission control technology, used to reduce nitrogen oxide (NOx) emissions in internal combustion engines. In high-pressure EGR systems, exhaust gases are redirected immediately after exiting the cylinder and mixed with the intake air. More recently, low-pressure EGR has become widely adopted to meet the stricter emission standards set by Euro 6 and Tier 2 regulations, offering improved efficiency in reducing pollutants.

EGR allows exhaust gas to be mixed in with intake air at varying amounts, as required. This means that less oxygen reaches the cylinder overall, leading to lower combustion temperatures. As a result, the amount of nitrogen oxides in the exhaust gas can be reduced by up to 50%. In petrol engines, this can also reduce carbon dioxide emissions and fuel consumption.

Internal EGR can be accomplished a few different ways. Valve overlapping can allow some exhaust gas to remain in the combustion chamber, or allow it to be sucked back into the cylinder from the exhaust manifold, along with the incoming air. Timing of the intake and exhaust valves can also be changed during running, by means of adjustable cams. This varies the amount of internal EGR as required by current conditions.

External EGR is accomplished when exhaust gas is routed from the exhaust, and is fed back into the fresh intake air through an external valve. The exhaust gas can be cooled, as needed, with an EGR cooler. External EGR can be designed with or without a bypass.

High-Pressure EGR In High Pressure EGR, some exhaust gas is removed immediately after the cylinders, upstream of the turbocharger. This exhaust is fed back into the intake air, after the throttle valve.

Low-Pressure EGR In Low Pressure EGR, some exhaust gas is removed downstream of the turbocharger, or only after any exhaust treatment system. This exhaust is fed back into the intake air, upstream of the turbocharger compressor. An exhaust gas lap provides the necessary exhaust gas back pressure, if the pressure difference is not sufficient for the required EGR mass low rates. This exhaust gas can also be cooled by a low-pressure EGR cooler.

Low-pressure EGR represents the state of the art with regard to diesel engines. The advantages of adding low-pressure EGR to high-pressure EGR include:

- Higher performance/ efficiency of the turbine

- Larger EGR map

- More homogeneous mixing of exhaust gas with fresh air via the compressor

- Lower NOx and particulate emissions

- Improved EGR cooling (through EGR and charge air cooler)

The disadvantages compared to high-pressure EGR include:

- Longer paths and additional components

- Possible hazard due to soiling or damage to the turbocharger compressor, e.g. through droplet impact

High-pressure EGR is primarily used in the case of a cold start or short-term state changes, e.g. when accelerating.

The low-pressure EGR valves from Pierburg generally consist of a centrally positioned butterfly flap in an aluminum pressure die-cast housing. The integrated actuating drive usually consists of a DC electric motor and a two-stage spur gear unit.

The low-pressure EGR combi valve simultaneously assumes the tasks of the low-pressure EGR valve and an intake air throttle.

The throttling results in a pressure gradient in relation to the intake side, causing the exhaust gas to low into the area in front of the compressor in a controlled manner. As a combined component, the low-pressure combi valve is not only more cost-effective, but also offers the benefit of a lower weight.

NOTE Typical damage in the area of the low-pressure EGR includes:

- Leakage in the exhaust gas lines or the coolant line

- Leakage in or on the EGR cooler

- Low-pressure EGR valve leaks / does not open or close

- Electrical actuation of the servo motor defective

To read more of this technical article or download the entire article click

here. There are lots more Tech Tips to view, and they are all searchable, on

TechTips.ie.

There are lots more Tech Tips to view, and they are all searchable, on TechTips.ie

There are lots more Tech Tips to view, and they are all searchable, on TechTips.ie