REPXPERT’s Alistair Mason, replaces the clutch in a 2008 Ford Focus 1.6 (petrol), which has covered more than 85,000 miles. With a book time of just shy of five hours and basic workshop equipment required, this is a profitable repair for any workshop.

A two-post vehicle lift, engine support, gearbox jack and clutch alignment tool are required, while the radio code and wheel bolt key should be close-to-hand as well.

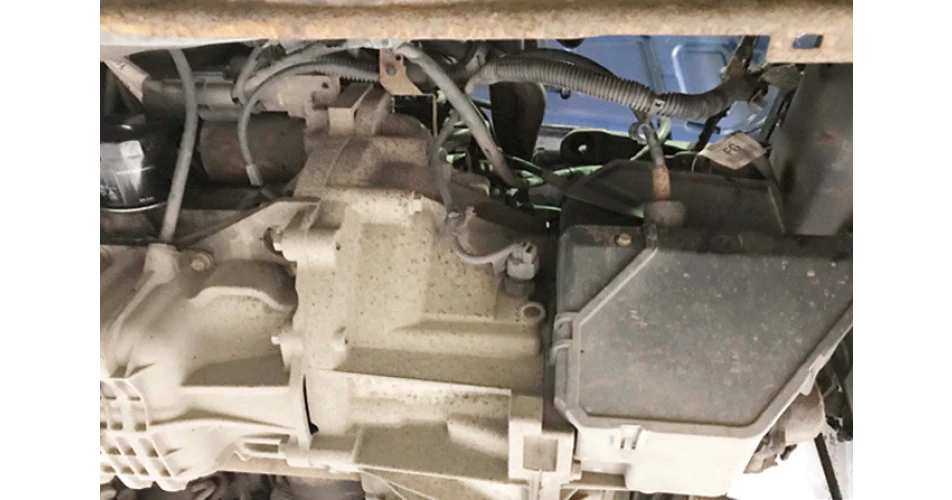

Gearbox removal With the vehicle placed on the vehicle lift, open the bonnet and remove the air filter assembly. Note, there is a small breather pipe that has to be disconnected (Fig 1). With the air box removed, do the same with the battery and battery carrier, which then gives good access to the top of the gearbox and bell housing area.

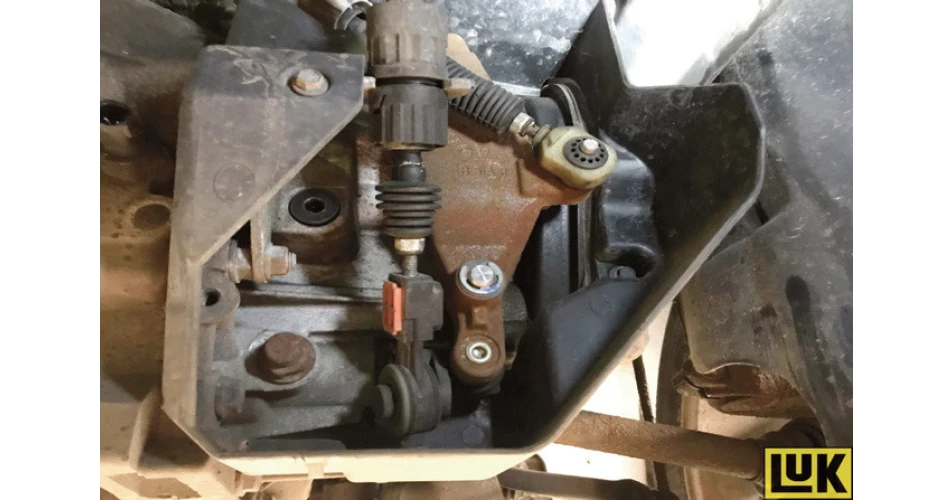

Raise the vehicle lift to gain access to the underside of the vehicle, remove the plastic gear-change cover (Figs 2 and 3), and disconnect the two gear-change cables, the reverse light switch multiplug and undo the lower bell housing bolts, leaving two easily-accessible to support the gearbox until removal.

Remove both front wheels, centre hub/driveshaft bolts, both front bottom ball joint nuts and disconnect the bottom arms from the hub assemblies. Detach the centre bearing carrier on the O/S driveshaft, slide the driveshafts out of the hub assemblies, lever the inner driveshaft joints out of the gearbox and remove both front driveshafts. A small amount of oil may drain when the driveshafts are removed, so an oil collection system may be required.

Remove the lower gearbox pendulum mounting, and remaining lower bell housing bolts. Support the engine with an engine brace or subframe mounted support. Lower the vehicle lift, remove the gearbox mounting, upper bell housing bolts and disconnect the hydraulic pipe from the concentric slave cylinder and blank as required.

Lower the engine/gearbox assembly slightly to aid gearbox removal, raise the vehicle lift if not already carried out, support the gearbox with a suitable transmission jack, undo the final easily-accessible bell housing bolts and ease the gearbox away from the engine. Once the gearbox input shaft is clear from the clutch, lower the transmission jack and remove the gearbox.

Clutch replacement With the gearbox removed, undo the six bolts that hold the clutch to the flywheel, ease the clutch cover off its dowels and remove the clutch cover and plate, inspecting the clutch area for any leaks from the engine or gearbox and rectify if required.

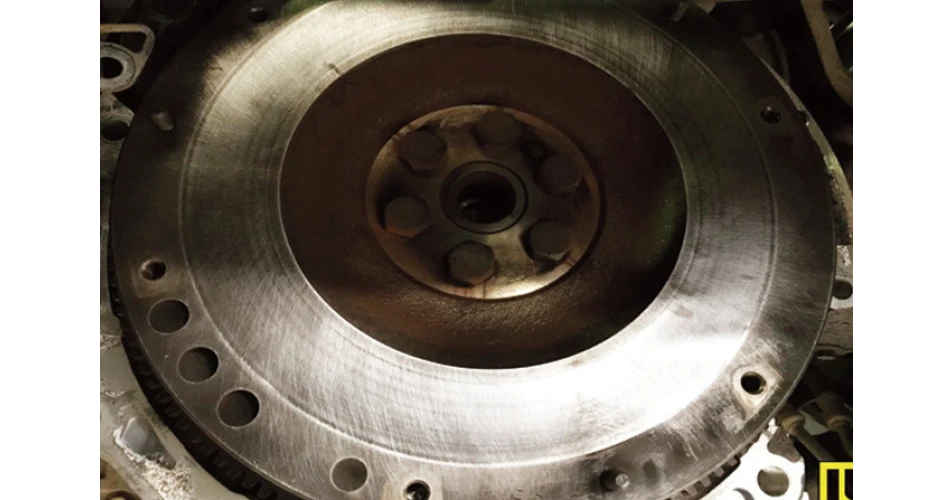

Clear the excess clutch dust using clutch and brake dust cleaner. Remove the ‘glaze’ from the flywheel surface using an Emory cloth and inspect for heat cracks (Fig 4), replacing if required, then clean ready for clutch installation.

Remove the concentric slave cylinder (CSC) from the gearbox, clean the bell housing with clutch and brake dust cleaner, mount the new CSC squarely on the cleaned surface, taking note of the bulletin inside the box, which instructs how to use the replacement retaining bolts supplied, as the new CSC body has been modified, and torque to the manufacturer’s specification. It is worth nothing that the new CSC can be prefilled with clean brake fluid to aid the bleeding process.

Apply a light smear of high-melting point grease on the gearbox input shaft, then slide the new clutch plate onto the input shaft, which will distribute the grease evenly and also confirm the clutch plate is correct for the vehicle. Remove the clutch plate and wipe off any excess grease.

Using brake and clutch dust cleaner, degrease the new clutch pressure plate, mount the new clutch plate using a clutch alignment tool and then mount the clutch, ensuring the plate is mounted correctly with gearbox side facing away from the engine. Insert and tighten the bolts evenly and sequentially.

It is always best practice to flush out the old hydraulic fluid from the hydraulic system; allow the old fluid to drain out, while replenishing the fluid as it drains. When running clear, clamp or block the hydraulic pipe as required.

Check all cables are clear of the clutch area, so they will not be trapped or pinched when the gearbox is installed, and ensure that the gearbox alignment dowels are located correctly.

Gearbox installation Mount the gearbox onto the transmission jack, then ease it into position, align with the engine and slide it into position, so it engages onto the alignment dowels and then secure with two easily-accessible housing bolts.

Bring the engine and gearbox back into position and refit the gearbox mounting, reinstall in reverse order of removal and top up the gearbox oil, if required.

The clutch can be bled using the vacuum bleeding method, which draws fluid and air out of the system. Reset all elec

Information on Schaeffler products, fitting instructions, labour times and much more can be found on the REPXPERT garage portal - www.repxpert.co.uk - the REPXPERT app, or by calling the Schaeffler REPXPERT hotline on (+44) 1432 264264.

To read more of this technical article or download the entire article click

here. There are lots more Tech Tips to view, and they are all searchable, on

TechTips.ie.

There is a small breather pipe that has to be disconnected

There is a small breather pipe that has to be disconnected

Remove the plastic gear-change cover

Remove the plastic gear-change cover

Remove the plastic gear-change cover

Remove the plastic gear-change cover

Remove the ‘glaze’ from the flywheel surface using an Emory cloth and inspect for heat cracks

Remove the ‘glaze’ from the flywheel surface using an Emory cloth and inspect for heat cracks

.png)

.png)