Blue Print has highlighted the importance of changing transmission filters to ensure optimum transmission performance.

Automatic transmissions are controlled by various electronic, mechanical and hydraulic components to optimise gearshift quality and feel. Clean transmission oil plays a major role in the operation of this very important powertrain component. The oil allows the gearshift to operate smoothly and efficiently, which is made possible by the use of quality filtration and the sophisticated ‘additive packs’ within the base oil.

Over time the transmission fluid and additives deteriorate, along with the filter (which is gradually contaminated), causing these carefully engineered transmission components to alter. This has a negative impact on the transmission’s performance, including harsh gear engagements, as the controlled clutch slip no longer responds as designed. These problems lead to rapid wear of the friction discs, solenoids and other transmission components and can cause expensive transmission failure, providing the transmission oil and filter are not regularly maintained.

The main purpose of an automatic transmission filter is to keep the oil clean from contaminants. This includes wear debris and impurity elements, which can be harmful to the automatic transmission. At the same time, the transmission oil must freely pass through the filter, ensuring of the necessary transmission flow capacity.

To ensure a transmission’s long life and smooth operation, Blue Print advise that regular transmission oil servicing is carried out according to the vehicle manufacturer’s recommended intervals, although this may need to be more frequent according to the operating conditions of the vehicle.

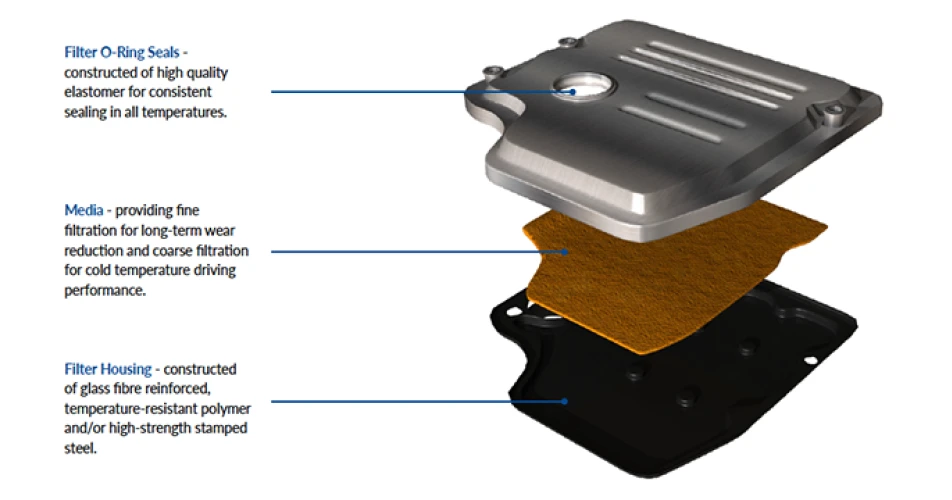

Each Blue Print transmission filter meets the specific requirements of its application and intended service life. The filtration efficiency is fine-tuned to match each transmission’s fluid cleanliness requirements in order to help guarantee transmission durability throughout its intended life cycle.

The filter media strength is tested to withstand the most extreme “debris” loads under severe wear conditions (i.e. at elevated temperatures) and is engineered to maintain fluid flow rates even as wear debris accumulates. The filter housings are constructed from advanced fibre reinforced temperature-resistant polymers or a combination of polymers and stamped steel.

Blue Print Transmission Filters are available nationwide from motor factor stockists.

.jpg)