Chicago Pneumatic has released another of it useful online expert articles, this time on the importance of wheel tightening to the correct torque.

The tool and equipment experts say this issue is often overlooked, but an incorrectly fitted wheel can have serious consequences on the safety of a vehicle and its passengers. Service professionals need to be able to remove and replace wheels quickly, but there is also a major safety element that needs to be part of the equation.

Over-tightened and under-tightened lug nuts can result in a potentially catastrophic failure of the wheel. Wheel nuts that are over-tightened risk being damaged, stretched and broken, especially when hitting potholes and bumps in the road. Wheel nuts that are under-tightened can back out or sheer off, causing premature wear and separation of the wheel from the hub. Irregular nut tightening on the same wheel is also a problem as it can lead to broken nuts, movement, vibrations and even wheel detachment.

Yann Pasco, Global Business Development Manager, Vehicle Service at CP says, “Mechanics and garage technicians that change tyres are ultimately responsible for ensuring that wheels are tightened correctly. Failure to do so can result in customer complaints, loss of repeat business and even litigation. The good news is that correct tightening is easily achievable without compromising efficiency and productivity.”

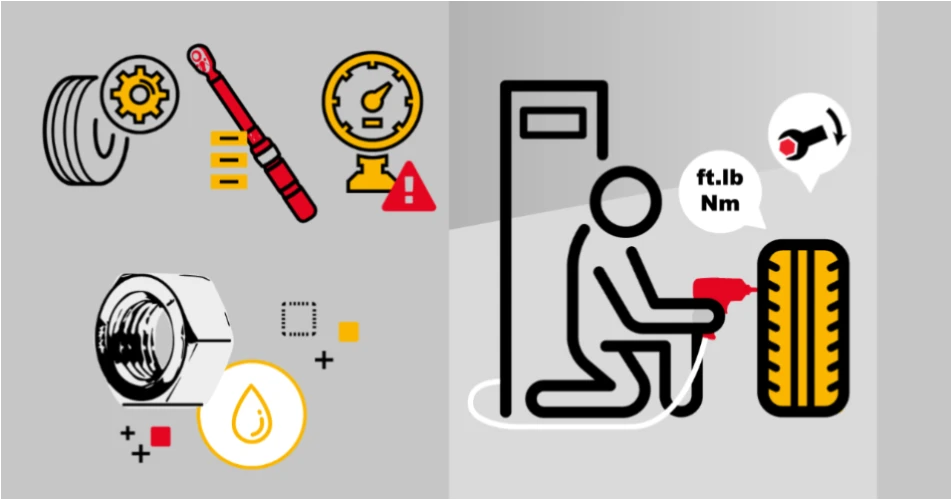

Wheels are correctly fitted when nuts are tightened to the torque specified by the vehicle manufacturer and the wheel is properly aligned with the hub. The right torque can be easily achieved through using the right tool for the job. For example, a classic impact wrench on the lower setting where the working torque of the tool does not exceed the required torque, or wrenches with a ‘torque limited’ TL feature which guarantees that the required torque is not exceeded. Jobs should be finished with a torque wrench to ensure the right torque of each nut.

Yann adds, “Torque wrenches are precision tools, so to ensure that they continue to deliver excellent performance, you should calibrate them once a year and keep them well maintained. Protect them from shock by storing them in their protective cases and reset them to the lowest value when not being used.”

He also sets out the following tightening tips:

- Inspect the nuts before re-assembling the wheel, to double check they are fit for purpose. If there are any fissures, deformation or fatigue then they will not be up to the job.

- Ensure the nuts and studs are clean. If any dirt (e.g. mud, salt or rust) has accumulated this will affect the quality of the tightening. This is particularly important after winter and there are specific tools and accessories to help, such as stud cleaners and small sanders.

- Lubricate the nuts and studs. This can be done using a small manual oil pump, placing 1 drop of oil between the nut and washer and rotating the washer to distribute the oil evenly.

- Follow the star pattern to tighten the nuts, i.e. tighten nuts that are opposite each other, rather than next to each other, first. This ensures good contact between the wheel and the hub