Brake hoses, despite their seemingly simple function, play a critical role in ensuring the effective transmission of brake fluid. German parts specialist febi has highlighted the vital role they play and the importance of high quality when replacing.

Brake hoses are flexible pipes that must withstand high pressure and continuous flexing. They require flexibility and movement to accommodate the action of the suspension and steering components without kinking or leaking. High-quality brake hoses must also resist the significant pressures generated during braking.

Despite their robust design, brake hoses are susceptible to various failures, often due to age, environmental factors, or mechanical stresses. Common issues include:

Without regular maintenance the high moisture content held within the brake fluid corrodes the internal metal components of the brake system, contributing to seized brake calipers, failing anti-lock brake modulators, and deterioration of the internal brake hose rubber which can cause blockages within the braking system.

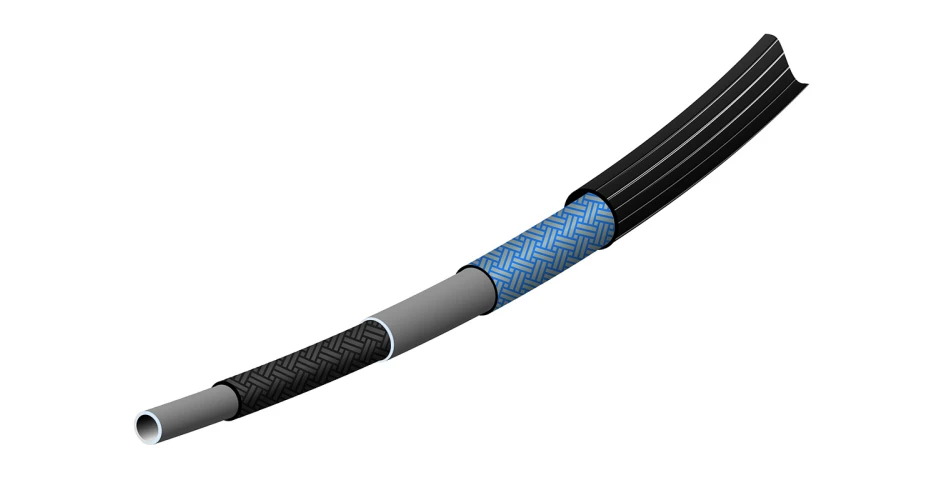

Brake hoses are engineered to meet stringent safety and performance standards. Typically, a brake hose is constructed from multiple layers. The inner tube is made from oil-resistant synthetic rubber to ensures a leak-proof channel for the brake fluid. The reinforcement layer is made of braided high-strength synthetic fibres and the outer layer is made of a weather and abrasion-resistant synthetic rubber.

The manufacturing process involves precision extrusion of the inner tube, braiding of the reinforcement layer, and final coating with the outer layer. Each hose undergoes rigorous quality control, including pressure testing, to ensure it meets industry standards.

febi brake hoses are then subject to burst pressure, flexibility, and chemical resistance tests to ensure the hose meets all required standards.

Regular inspection and timely replacement of brake hoses can prevent potential brake failures, ensuring the safety and reliability of the vehicles on the road.

The entire range of brake hose replacement parts can be found at: partsfinder.bilsteingroup.com