Many control units share information provided by multiple sensors built into the vehicle’s infrastructure, to give important data feedback that affects vehicle emissions, performance, comfort, active and passive safety and much more. When a vehicle’s battery is replaced, some sensor and actuator resets may be required, and a fault in a system can prevent others from being reset. febi recounts how one Golf was affected by a bad wheel bearing.

Common driver comfort items, such as radio, clock and one-touch window settings, are mostly universal. However, many other items that affect the braking, steering and navigation systems are usually vehicle specific and rely on all systems being fully functional. If any part of the system is faulty, a reset adjustment may not be possible. This was the case with a Volkswagen Golf V, which recently had a battery replacement. The assisted steering, electronic power control (EPC) and electronic stability program (ESP) warning lamps, were all illuminated.

The vehicle’s stability control program is an integrated part of the brake control unit. It processes and acts on data shared by many other control units during the operation of steering, braking and acceleration to control the vehicle.

An attempt had been made to reset the steering wheel angle sensor with a diagnostic tool, but that failed, leaving the warning lamps illuminated and the stability safety system non-functioning.

A global fault code check of all systems, revealed a steering wheel angle sensor fault in the electromechanical steering control unit. However, on checking the data within the brake and steering control units, the steering wheel angle sensor appeared to be working correctly, but it was unable to reset to a known base position. The conclusion was that there must be another fault in the system that was causing the fault. After a short road test, it was revealed that the left rear wheel speed was different than that of the other wheels.

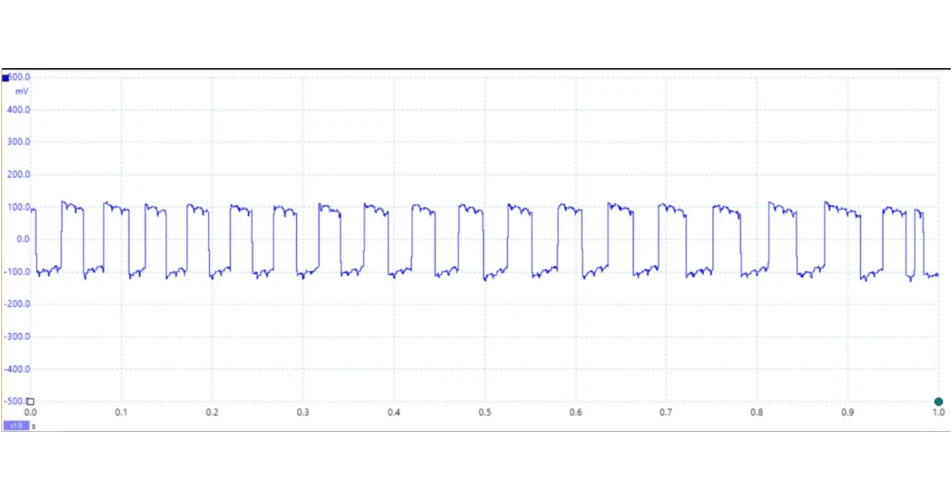

An oscilloscope was connected to the left rear wheel speed sensor, to check the integrity of the signal. On checking the signal, there was an inconsistency in the square wave signal. (Fig.1)

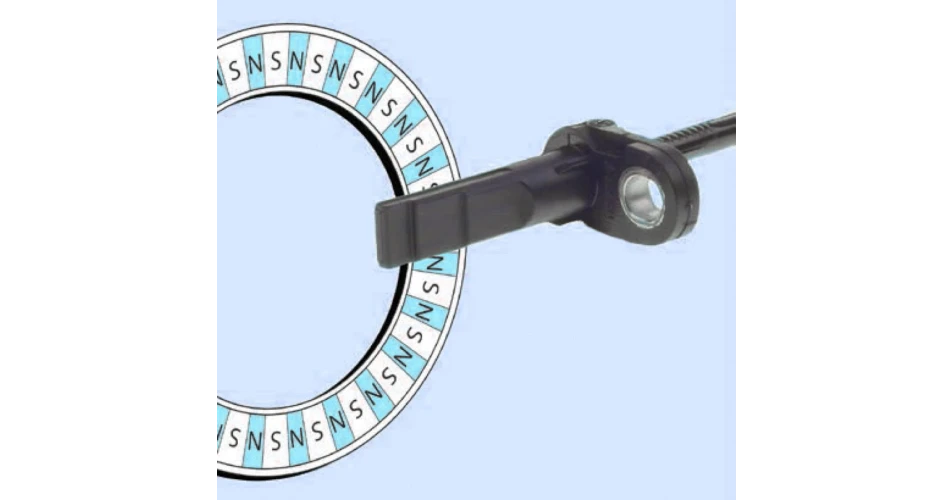

The wheel speed sensor is mounted in the hub at right angles to the magnetised impulse reluctor ring, which is mounted on the wheel bearing assembly. The active wheel speed sensor makes use of the magnetic resistive effect; a magnet in the sensor produces a magnetic field with the lines of magnetic flux running at right angles to the sensor layer. Deflection of the lines by the impulse wheel, causes changes in resistance in the thin ferromagnetic layer of the sensor element. (Fig.2) The sensor converts the changes in resistance into voltages. The square wave voltage detected by the brake control unit is a measurement of individual wheel speed, which is used to derive the acceleration and deceleration of wheel speed and is definitive for brake control.

A visual inspection of the sensor was required in order to see if there were any mechanical issues causing the inconsistency in the signal. This involved removing the wheel, brake disc, pads and caliper. The wheel hub with the integrated reluctor ring was removed.

With the wheel bearing assembly removed from the stub axle, it became obvious what had been causing the issue. Corrosion between the ferrous metal of the wheel hub and the magnetic reluctor ring had caused distortion to the reluctor, causing cracking of the magnetic ring and a narrowing of the air gap between the reluctor and the wheel speed sensor. This was the primary fault with the vehicle. (Fig.3)

febi wheel bearing kit (23320) was required as the replacement part. The wheel speed sensor (23810) was also replaced, because it had sustained some light damage from the distorted reluctor ring. The new bearing assembly and the wheel speed sensor were fitted to the car, along with the brakes and wheel.

Once this was completed, the steering wheel angle sensor reset could be carried out. This consisted of road testing the vehicle with an assistant to operate the diagnostic tool. This involved driving straight at no less than 20 km/h, turning the steering wheel at least 15° to the left and then to the right and then stopping the vehicle. Then, the steering was turned completely to the left and was held for at least 3 seconds, then back to the centre. This was followed by the turning of steering all the way to the right and then being held for 3 seconds and back to the centre again. Once this procedure was carried out, the sensor was reset and all systems were fully functioning again.

To read more of this technical article or download the entire article click

here. There are lots more Tech Tips to view, and they are all searchable, on

TechTips.ie.

Fig 1. The left rear wheel speed sensor was inconsistent, indicating a possible mechanical fault at the bearing

Fig 1. The left rear wheel speed sensor was inconsistent, indicating a possible mechanical fault at the bearing

Fig 2. The sensor detects the rotating magnetic feilds on the face of the bearing

Fig 2. The sensor detects the rotating magnetic feilds on the face of the bearing

Fig 3. The reluctor within the bearing was distorted, cracking the magnetic ring and was the source of the problem

Fig 3. The reluctor within the bearing was distorted, cracking the magnetic ring and was the source of the problem