The phenomena of noise, vibration and harshness can impact on the driving experience of any vehicle. Blue Print says there are many factors that must be considered to suppress brake noise and vibrations.

High pitched noise is created by vibration between the brake pads and discs. These are transmitted to the brake callipers and as a result, the entire brake system resonates to produce unpleasant noise. These include the quality of materials, the shape and torsion of the components, the driving environment, vehicle speed and brake temperature.

Noise is often caused from the vibration of the pad against the disc where full contact is not taking place or failing or faulty parts such as shims and pins which have lost their tension and create sound waves. These sound waves can either be the high pitched vibrations audible vibrations, or a low pitch vibration which you can feel.

During the development of a new Blue Print brake pad, many technologies are used in order to improve the comfort for both the driver and passengers by minimising these unpleasant vibrations and noises. Blue Print matches or exceeds the specifications of the OE brake pad, therefore retaining the original manufacturer’s benefits and features, such as chamfering and/or the addition of slots to ‘tune’ the pad so it makes less noise. The chamfers and slots change the natural frequency at which the brake pad oscillates so it runs quieter than a brake pad without these features.

There are also various types of shims which may also be fitted to the steel backing plate to dampen vibrations between the pad and caliper. These shims act like a cushion absorbing noise-producing vibrations. Some shims may have a half moon cut-out present, which allows the piston to push the brake pad at a desired angle, thus reducing noise and creating a more unified and even pad wear. These are generally fitted to directional brake pads which can only be installed in one direction.

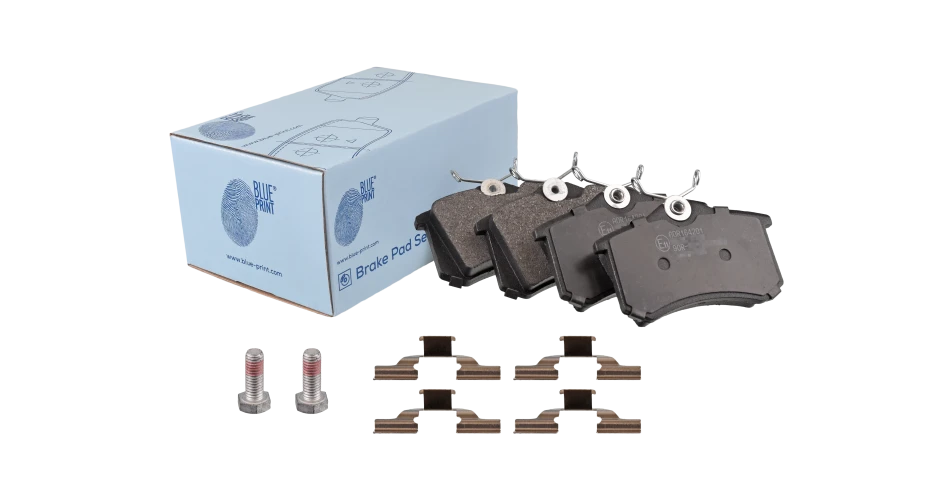

Brake pads may also come supplied with anti-rattle clips or springs that minimise play between the pads and caliper to further dampen vibrations during the initial engagement of the pad. There are also pads with additional weights with these added during the development phase to minimise vibrations and noise.

Blue Print says that when servicing and replacing friction components of a brake system, there are several important parts that need to be checked to both ensure for correct functionality and to minimise unwanted brake noise. These include the condition of the brake calipers and carriers, plus any other hardware, to see if they are worn or corroded. When fitting new brake pads, the technician should make sure all corrosion is removed from the pad and caliper abutment points and fit the new brake hardware.

The abutment points should be lubricated to ensure free movement and efficient braking by using the Blue Print anti-seize ceramic paste. The use of copper grease should be avoided as this can potentially affect ABS signals and encourages galvanic corrosion. It also prevents the brake pad from moving freely, which can also be a source of noise.

If the brake discs are heavily scored or lipped, they too, will need replacing as the rough surfaces cause noise. The technician should also make sure the hubs are clean and check for lateral runout by using a dial test indicator. They should then check the tolerances with the vehicle manufacturer’s data before fitting the new discs.

It is important to clean the hub surfaces before replacing the brake discs, otherwise brake judder could occur. For quiet, effective brakes, quality braking parts and the appropriate accessories should be fitted.

The entire range of braking parts from Blue Pint can be found at: partsfinder.bilsteingroup.com