While not being adopted by as a mainstream solution across the automotive industry, certain car manufacturers have utilised automated manual transmissions. These ASG or AMT systems are especially prominent on Smart vehicles. Replacement requires specialist knowledge and ZF Aftermarket, which has spare parts under its Sachs brand for many vehicles with ASG, has provided some helpful advice.

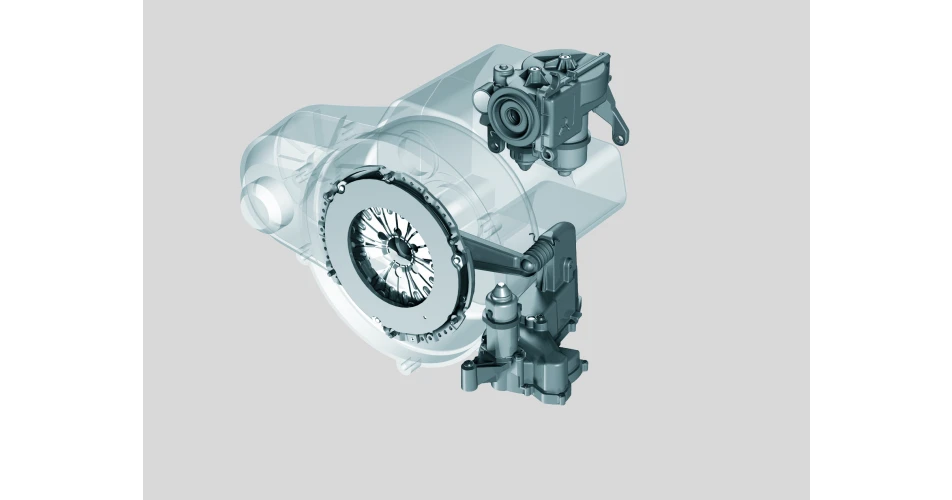

Automated manual transmission was introduced as an alternative to automatic transmissions with torque converters about 20 years ago. It was based on the conventional manual transmission in a countershaft design including a dry clutch and was equipped with hydraulic or electric actuators that operated the clutch and changed gears.

Smart equipped 100% of the first two generations of its two-seater vehicle with this drive variant. These models were built between 1998 and 2015. Other manufacturers who opted for the ASG were Citroën, Dacia, Renault and Iveco. Even the Volkswagen Group equipped its miniature car series and the corresponding Skoda and Seat models with ASG from 2013.

In general, automated clutches are stable and less prone to problems. Since engagement is performed by an electronically controlled actuator, operating errors by the driver are not an issue. Driving at too low a speed is also avoided by the automatic gear change. Nevertheless, even automated clutches wear out at some point. The correct installation of the spare part is then crucial, especially as the electronic actuation works according to fixed parameters. If the output values, according to which the control unit works, are not correct, this can, for example, lead to starting issues.

Sachs recommends careful inspection of the entire component before installation, paying particular attention to the side impact. For this ZF Aftermarket provides a side impact tester. If the limit value of 0.5 millimeters is exceeded, the mechatronics engineer should eliminate the lateral runout of the clutch disc with the help of a straightening fork.

Apart from the clutch itself, damage can also occur on the actuator. These components can only be replaced in their entirety, but this is relatively straightforward as there is only an electrical connection to the vehicle. For some models the workshop has to adjust the preload of the actuator by spring balance. For other vehicles, the workshop must first learn how to use the diagnostic device, whereby the transmission control unit determines the grinding point of the clutch.

ZF says if the workshop team observes basic rules such as extreme cleanliness and correct centring of the clutch before assembly, then a successful repair can be completed.