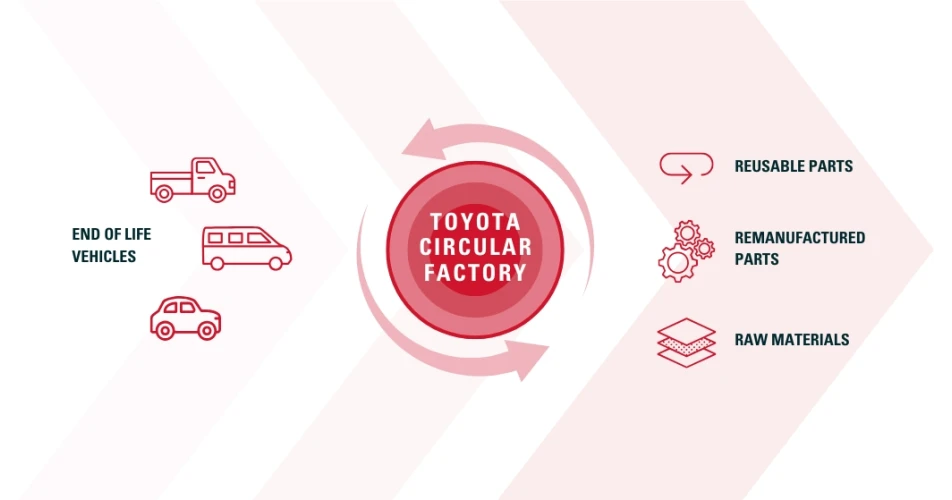

Toyota Motor Europe recently announced the establishment of the Toyota Circular Factory (TCF) to provide careful and systematic processing of vehicles at the end of their life, to maximise the environmental benefits of recycling, repurposing and remanufacturing.

The first TCF will be at Toyota Manufacturing UK’s Burnaston plant in Derbyshire. Activities will begin during the third quarter of this year, to develop a centre of excellence for future recycling operations across Europe and worldwide.

TCF processing focuses on three key areas: reusable parts; commodity items that can be re-manufactured and materials that can be recycled.

Following a comprehensive validation process, reusable parts will be reintroduced to the market through retailers or distributors. Commodity items such as batteries and wheels will be assessed for their potential remanufacture, repurposing or recycling.

Toyota also intends to recycle raw materials such as copper, aluminium, steel and plastic. These could then replace virgin materials as much as possible, in the production of new vehicle parts.

Leon van der Merwe, Toyota Europe Vice President of Circular Economy, said, “We initially anticipate recycling around 10,000 vehicles a year in our UK facility, which will give new life to 120,000 parts, recover 300 tonnes of high-purity plastic and 8,200 tonnes of steel, among other materials. As a next step, we plan to roll out similar operations across Europe. And we’re not stopping at our own facilities, we are eager to collaborate with other organisations who share our passion for circularity and commitment to carbon neutrality.”

With this initiative, Toyota aims to significantly reduce future emissions associated with vehicle and sub-component manufacturing. This effort aligns with the company’s global and European sustainability objectives and sets a new industry benchmark for responsible recycling and material reuse.

Toyota Europe is committed to being fully carbon neutral by 2040 and achieving carbon neutrality in all its owned facilities by 2030. By 2035, Toyota plans to have 100 per cent CO2 reduction across its European product line-up.