When it comes to installing tensioner pulleys, care has to be taken to make sure it is done correctly. Sometimes the design of the replacement pulley is different to what was previously installed, and a mechanic has to pay close attention to see the subtle differences in the design that changes the installation procedures.

Different tensioning pulleys depending on design of crankshaft drive sprocket (round or oval)

Various Ford/ PSA/ Volvo 1.6L diesel (Part nos. CT1162K2/ K3/ K4 and WP2/ WP3/ WP4) Problem Different vehicle manufacturers use different timing belt kits, with three different tensioning pulleys (V56664, V56675, V56676) that all look the same. The catalogs usually list two different timing belt kits for each vehicle, with the selection depending on the year of manufacture. However, the year is not always a reliable way to determine which is needed. To make sure, check the shape of the crankshaft drive sprocket (oval or round design). Installing the wrong kit may result in noise or, in the worst case, failure of the belt drive.

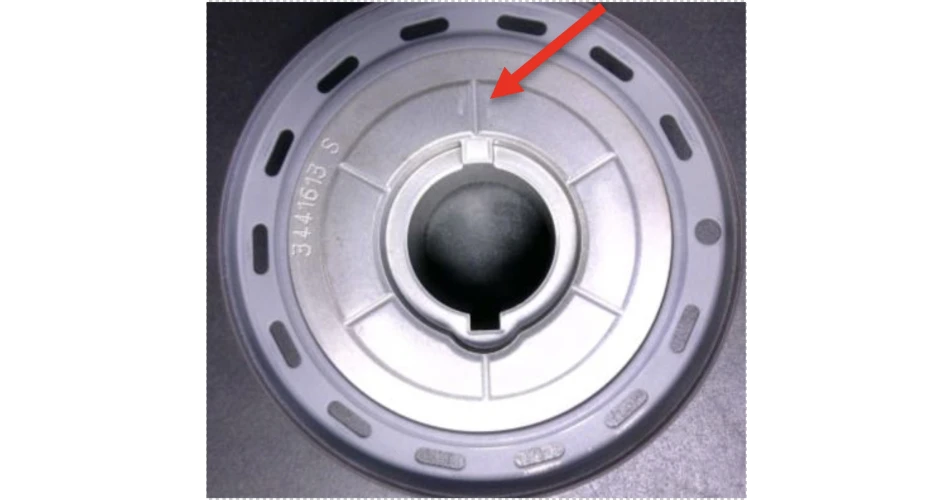

Cause Different tensioning pulleys have different tension spring rates. The rate must be suitable for the crankshaft drive sprocket installed at the factory. In recent years, the manufacturer has brought in an optimised timing drive with an “oval” sprocket. The two designs of sprocket look the same at first glance. To see which it is, take it off and check whether there is a recess drilled in the back.

Solution For the crankshaft sprocket with no recess (round design), always use the timing belt kit CT1162K2/ WP2 with tensioning pulley V56664. If the sprocket has a recess (oval design), you need either kit CT1162K3/ WP3 with tensioning pulley V56675 or kit CT1162K4/ WP4 with tensioning pulley V56676. If both kits are listed for the vehicle, it is the year of manufacture which is the decisive point. To be sure, check the part number on the back of the tensioning pulley.

Incorrect setting of the tensioner pulley can cause engine damage

PSA 1.6 HDi / BlueHDi, Ford 1.5 TDCi (Part nos. CT1203, CT1203K1, CT1203WP1)

Problem Teeth have been sheared off the timing belt, the tensioner pulley arrester body is torn and the full load stop is incorporated.

Cause During the tensioning procedure, the hole in the tension indicator is brought into contact with the hole in the arrester body. As a result, the tension is set far too high and the full load stop is incorporated by the recurring clash with the arrester body until it finally tears or aborts.

Solution The tension indicator must be set centrally in the recess of the arrester at the end of the tensioning procedure. Observe the tensioning direction.

To read more of this technical article or download the entire article click

here. There are lots more Tech Tips to view, and they are all searchable, on

TechTips.ie.

Small variations in tensioner designs can change installation procedures

Small variations in tensioner designs can change installation procedures