Replacing the battery on a modern vehicle is no longer a straightforward fit-and-forget task. On vehicles with advanced technology, such as Start-Stop, battery replacement can be complex and time consuming. Ian Newham, Training Manager for GS Yuasa Battery Sales UK, explains the differences to be aware of and mistakes to avoid.

Battery Specification For vehicles with advanced technology, it is essential the battery is replaced with one of the correct specification. If a vehicle is fitted with an AGM Start-Stop battery, then the replacement must also be AGM Start-Stop. The same applies to EFB equipped vehicles. Unlike standard ignition vehicles, it is not possible to replace the battery with a lower capacity model. Although this would physically fit, it would cause serious problems.

Battery Testing Checking the health of an EFB or AGM battery should be done using a conductance battery tester. It is important to select the EFB or AGM setting on the tester, to ensure that the results are accurate for EFB or AGM batteries.

Battery Location On many new vehicles, the battery is not fitted under the bonnet, and locating it can take time. The replacement process can also be extremely time consuming, with the removal of trim panels and seats when required. For some BMW and Audi models, replacing the battery can require up to an hour and a half of work.

Battery Management System and Battery Validation Battery validation is rapidly becoming a mandatory requirement, as part of the procedure for battery replacement. Most modern vehicles come fitted with a Battery Management System (BMS). This must be reset through the on-board diagnostics (OBD) port, to tell the vehicle when the battery has been replaced. The BMS monitors the battery throughout its service life, to maintain optimum charge efficiency, ensuring the operation of the Start-Stop system.

Failure to fit the correct battery, or reset the BMS, can cause serious issues such as battery failure, in car error messages, non-critical vehicle system shut-down and even complete loss of Start-Stop functionality. Most workshop diagnostic platforms are equipped with the capability to validate new batteries to vehicles. Alternatively, the Yu-Fit Battery Configurator offers an easy to use handheld solution.

Yuasa and GS Online Battery Lookup GS Yuasa provides several easy-to use tools to make the entire replacement process much easier. The online battery lookup systems can be accessed by visiting fit.yuasa.com for Yuasa batteries, or fit.gs-battery.com or by pushing a Yuasa or GS USB smart button.

The system will then identify the correct battery and show important details including estimated fitting time, battery and OBD location, technical data sheets and battery replacement procedures.

Yuasa and GS Yu-Fit Battery Configurators The Yu-Fit Battery Configurator provides a user friendly diagnostic tool for quickly and properly installing batteries. Although garages may already own diagnostic equipment capable of battery configuration, the Yu-Fit provides a simple unit dedicated to this task.

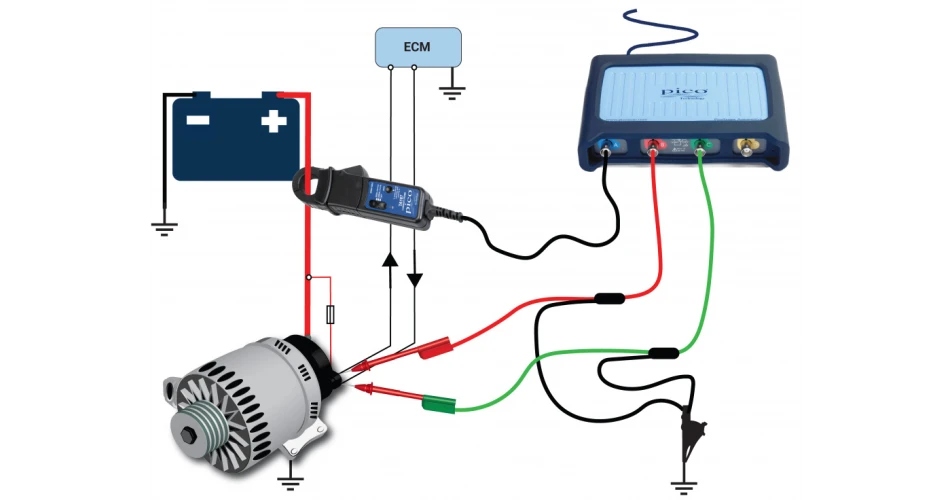

Battery Management System Alternator Testing The Battery Management System features an intelligent alternator. The output of the alternator is based on battery status and vehicle operating conditions. The alternator regulator is now capable of varying the alternator energising voltage, based on the request signals it receives from the BMS, and is also capable of providing a feedback response to the BMS with actual charging data. This means that the alternator output is variable and, in some cases, the BMS can switch the alternator off, which means that traditional diagnosis of a charging system using a multimeter, is no longer possible.

If a vehicle equipped with this system has a suspected battery or charging system fault, it is essential that an appropriate accurate charging system diagnosis is carried out using suitable equipment. Checking for the presence and accuracy of the BMS and alternator request and feedback signals, using an oscilloscope to interrogate the system, is the only way.

Remember: - Alternators cannot be condemned as faulty before checking for the presence of the request and feedback signals between the alternator and the BMS.

- The charge warning lamp is no longer controlled by the alternator directly as there is no longer a D+ connection on the alternator.

- Intelligent alternators specified for vehicles featuring a BMS look like those of a traditional fixed output alternator but must never be confused as they are not interchangeable.

You can see this Yuasa TechTip

here or see all TechTips

here.

An alternator operating with a BMS must be checked with a scope

An alternator operating with a BMS must be checked with a scope

The Yu-Fit dedicated Battery Configurator is easy to use instead of a complete scan tool

The Yu-Fit dedicated Battery Configurator is easy to use instead of a complete scan tool