Technicians are now working on vehicles fitted with a turbocharger on a daily basis, so to help them with this responsibility, Nissens Automotive has made available a comprehensive technical resource they can draw from. The company also wants to highlight lubrication of turbos is one of the key factors that will determine their lifespan.

“Particularly because of the ultra-high speeds at which they spin and the intense heat they have to operate under, the correct lubrication of a turbo is critical,” says Nissens Automotive’s Marketing Manager, Jan Zieleskiewicz. “If the lubrication is unimpaired, they are remarkably robust components that remain extremely reliable. However, if impaired, the results can be catastrophic and lubrication issues are among the most common reasons for their failure.”

Jan adds, “To assist technicians to diagnose problems and correctly rectify faults, we have developed several online resources, including a section headed Lubrication Starvation, Friction and Seizure

https://support.nissens.com/material/premature-turbocharger-failures, which highlights the most common reasons for premature turbo failure, how to avoid them and how any underlying problems can be solved.”

Jan also point out that one of the most common causes of lubrication problems is crankcase ventilation, although ironically, this is an issue that is often disregarded, which is why Nissens has developed a specific section

https://support.nissens.com/material/engine-crankcase-ventilation to address the subject.

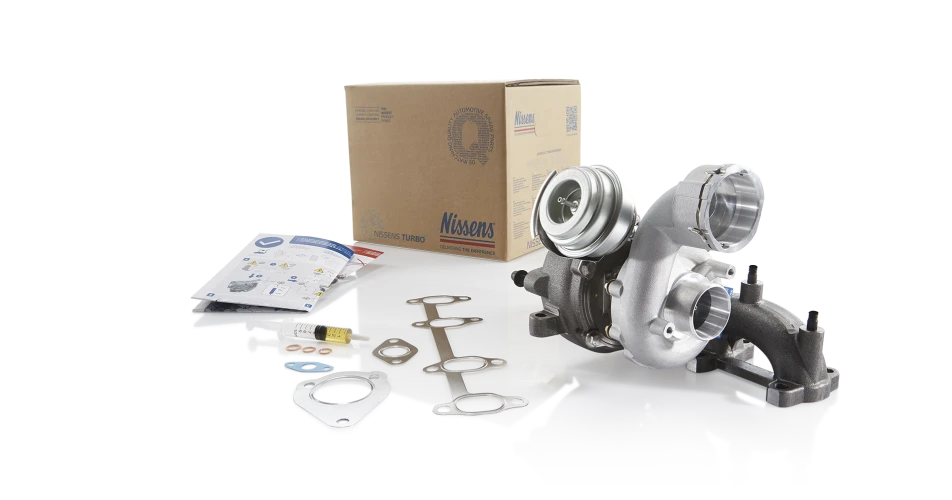

“Naturally, when failure does occur and the turbo needs to be replaced, Nissens Automotive is able to satisfy the needs of independent workshops with a range that has been designed and manufactured to match the specifications of the original components to replicate the engine performance, fuel economy, emissions standards and durability stipulated by the VMs.

Turbo failures are often accompanied with, or caused by, problems with related components, so Nissens Automotives also includes additional products such as turbo intercoolers, and oil feed pipes, which, as a best practice procedure, it is recommend are replaced at the same time as the turbo.

Jan says, “When it comes to fitting a replacement turbo, the correct installation procedure is critical and here again Nissens provides technicians with the necessary guidance

https://support.nissens.com/material/self-learning-course-turbocharger-component-installation to enable them to fit it right, first time.

For more information concerning the entire Nissens Automotive turbo solution, there is a host of support material, including technical insights, available via:

https://support.nissens.com/en/search/turbo.