OE and aftermarket suspension parts specialist ZF has issued some important safety advice regarding component replacement.

Shock absorbers maintain tyre-to-road adhesion for good grip and braking. If they or other suspension components are worn, optimum contact is reduced, resulting in longer braking distances and compromised handling, especially during critical avoidance manoeuvres. In addition to this vehicle safety systems such as anti-lock braking and traction control can only function perfectly if all suspension elements are in faultless condition. For this reason says Wayne McCluskey, Technical Training Manager at ZF Aftermarket, says when replacing a suspension component, all other parts of the system should be thoroughly inspected for wear, to maximise safety and prolong the life of newly fitted items.

If for example a new shock absorber is being fitted, the condition of ball joints and rubber-to-metal components such as control arm bushes and suspension top mounts should be checked before or during dismantling. Wear in any of these areas can lead to excessive play in the joints, subjecting the shock absorber piston rod to bending stresses beyond its design limits. One possible consequence is that the threaded pin suffers a fatigue fracture where it joins the piston rod or another failure mode is side loading of the piston rod rapidly wearing both its chromium plating and its oil seal, causing the shock absorber to leak.

To preserve fuel economy and minimise emissions, vehicle manufacturers increasingly specify lightweight aluminium alloy forgings for suspension components such as track control arms. Faced with weight constraints, the designer may create the part with the intention of it being replaced when wear occurs, rather than overhauled. Vehicle repairers should therefore check whether the manufacturer of the vehicle or component recommends that aluminium control arms are replaced as complete assemblies. Even using a hydraulic press and the correct press tools, driving out old bushes and inserting replacements can tear out minute alloy fragments from the bush housing, leaving a less stable joint. Plus, the risk of nicking the alloy with a tool in the process and forming a nucleus for stress concentration could ultimately cause a fatigue failure.

ZF also point out that when replacing any suspension components, a basic rule is to always replace in axle pairs to maintain safe, balanced handling and ride comfort. They also stress the importance of insisting on original equipment aftermarket parts. This not only ensures compatibility with the original vehicle specification, but also brings the benefits of any component modifications or upgrades made by the manufacturer. For example, the rubber-to-metal front subframe bush used in several VW Group vehicles including the Seat Cordoba (6L2), Seat Ibiza IV (6L1), Skoda Fabia (6Y2, 6Y3, 6Y5), VW Fox (5Z1, 5Z3) and VW Polo (9N).

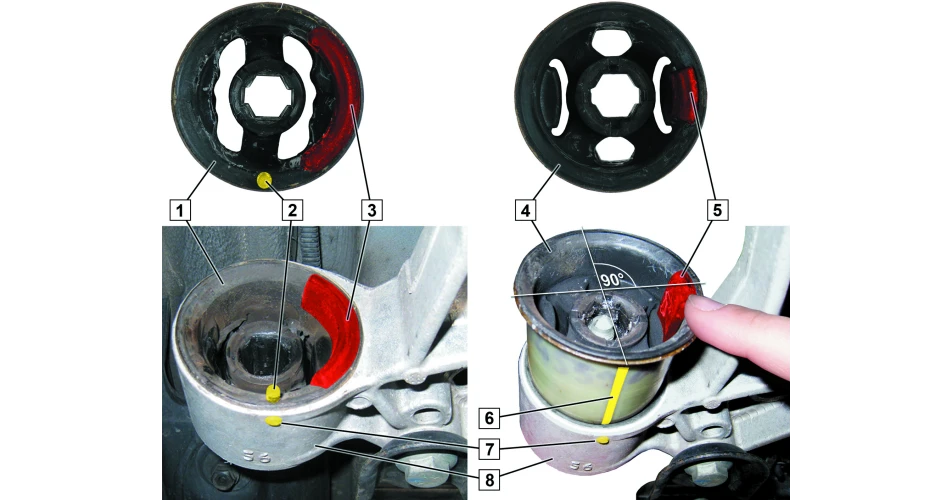

The original part number 29710 01 (Illustration, item 1) has been replaced with an improved design, part number 34559 01 (item 4). Unlike the original, the new bush does not have a raised rubber plug (item 2) to align with a corresponding mark on the front axle support item 7 – this is cast below the bush housing on the right-hand side of the vehicle, and above the housing on the left-hand side). The absence of the reference point could be misconstrued as meaning alignment is unnecessary following the redesign, but to achieve the desired handling and ride characteristics, it is important the new bushes are correctly oriented during installation. To achieve this, the area on the bush where the control arm makes contact (item 5), must point to the axle support or towards the centre of the vehicle. A mark (item 6) can be made on the bush at 90 degrees relative to the contact area, which is then aligned with the mark on the axle support before pressing the bush into position with suitable tooling.

ZF says having completed any component replacements, fasteners should only be tightened to their final torque setting with the full weight of the vehicle on the wheels. If tightened prematurely, a twisting strain will be imparted to bushes or pins as they alter position when the vehicle is lowered.

VW front subframe bush. Original part number 29710 01 (left) has been replaced with an improved design, part number 34559 01 (right).

VW front subframe bush. Original part number 29710 01 (left) has been replaced with an improved design, part number 34559 01 (right).