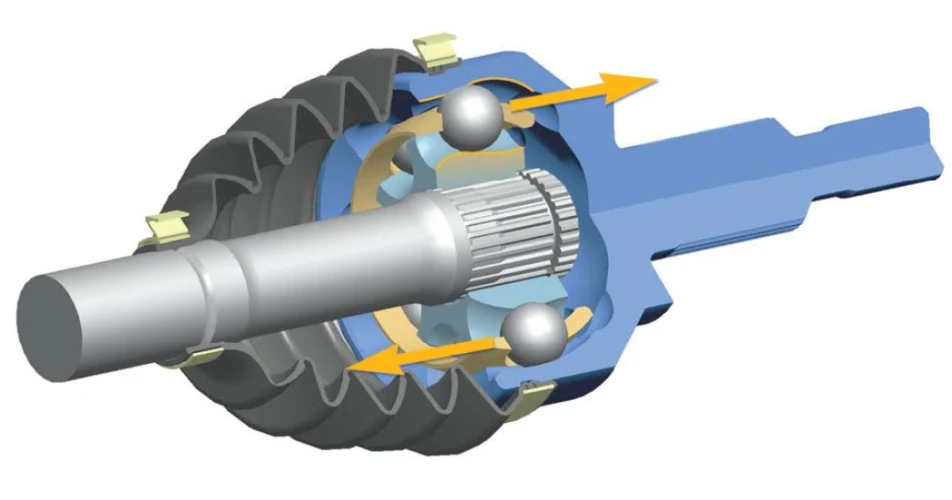

To reduce space required for power train components, GKN has developed the Countertrack joint which transfers the same power with a considerably reduced diameter, providing a size reduction of up to 10%.

This is made possible through the use of an S-shaped track profile and the counter-running ball tracks. This innovative design makes it possible to reduce internal friction, heat and size and to increase the transferable torque and maximum bending angle. This offers benefits such as;

- Power loss is reduced by 30% over the entire bending angle

- Weight is reduced by 15% with higher power values

- Thanks to the reduced heat level, up to 25% greater torque can be accepted and transferred

The great reduction in weight which comes along with the development of new vehicle models also provides benefits in terms of fuel consumption and CO2. It has also been possible to extend the wheelbase without losing power. This gives developers more interior space and enables driving characteristics to be improved.

These joints, which GKN also refers to as SX, are now available as aftermarket parts.

GKN says that GKN SX joints are not exchangeable with other designs as drivers would immediately recognise a significant difference in turning circle. Conventional compact joints also do not offer the sideshaft as much space for movement which can lead to joint damage.